Fastenboen's Conical Knurled Spring Washer represents a breakthrough in mechanical fastening technology, combining advanced materials, precision engineering, and innovative design to deliver superior performance in demanding environments. This article explores the product's technical specifications, engineering advantages, and real-world applications, while highlighting the expertise of HEBEI A&Z INTERNATIONAL CO., LTD., the company behind this cutting-edge solution.

Technical Specifications

The Conical Knurled Spring Washer is engineered to meet the highest standards of durability and performance. Below is a comprehensive overview of its key specifications:

| Attribute | Specification | Engineering Advantage |

|---|---|---|

| Material | 304/316 Stainless Steel (AISI Compliant) | Salt spray resistance 500+ hrs (ASTM B117) |

| Design | Conical spring + 360° knurled contact face | 200% higher anti-vibration force vs. standard serrated washers |

| Locking Mechanism | Radial knurls bite into substrate | No pre-drilling Zero galling on soft metals |

| Fastener Sizes | M3 to M16 (DIN 6796 / ISO 10683) | Full compatibility with ISO metric bolts |

| Temperature Range | -55°C to +300°C (316SS variant available) | Suitable for aerospace/automotive |

| Certifications | RoHS 3, REACH, DIN 6796 Type A | Global compliance guaranteed |

Engineering Advantages

The Conical Knurled Spring Washer's design and materials provide significant advantages over traditional fastening solutions:

Enhanced Vibration Resistance

The conical spring design combined with a 360° knurled contact face creates a 200% increase in anti-vibration force compared to standard serrated washers. This makes it ideal for applications in high-vibration environments such as automotive and industrial machinery.

Superior Corrosion Resistance

Constructed from 304/316 stainless steel, the washer exhibits salt spray resistance of over 500 hours (ASTM B117). This makes it suitable for marine, chemical processing, and other corrosive environments. The National Institute of Standards and Technology (NIST) emphasizes the importance of corrosion resistance in critical infrastructure, stating that "materials must withstand environmental stressors to ensure long-term reliability" (NIST).

Efficient Locking Mechanism

The radial knurling design allows the washer to bite into the substrate without requiring pre-drilling, reducing installation time and minimizing the risk of galling on soft metals. This feature is particularly beneficial in aerospace applications where material integrity is critical.

Applications and Use Cases

The versatility of the Conical Knurled Spring Washer makes it suitable for a wide range of industries:

Aerospace Industry

The washer's temperature range (-55°C to +300°C) and compliance with DIN 6796 Type A make it ideal for aerospace applications. Its ability to maintain integrity under extreme conditions aligns with NIST's standards for materials used in critical systems (NIST).

Automotive Manufacturing

With its compatibility with ISO metric bolts (M3-M16), the washer is well-suited for automotive assembly lines. Its vibration resistance helps prevent loosening in high-speed vehicle components.

Industrial Machinery

The washer's robust design and corrosion resistance make it a reliable choice for industrial equipment operating in harsh environments. The NIST highlights that "precision-engineered fasteners are essential for maintaining the reliability of industrial machinery" (NIST).

Company Background: HEBEI A&Z INTERNATIONAL CO., LTD.

HEBEI A&Z INTERNATIONAL CO., LTD. has established itself as a leader in the fastening solutions industry, with over 20 years of global export expertise. The company's commitment to quality and innovation is evident in its comprehensive service offerings:

- Reliable After-Sales Support: Swift resolution for all technical issues and product inquiries.

- 20+ Years of Global Export Expertise: Proven experience in international logistics and compliance.

- Detailed Product Specifications On Request: Customizable spec sheets for informed purchasing decisions.

- Instant Quote Response: Submit inquiries for prompt pricing and solution proposals.

- Certified Export Documentation & Timely Shipment: Hassle-free logistics with professionally prepared export papers.

- Custom Packaging with Pre-Shipment Visual Verification: Branded/secure packaging with photo confirmation before dispatch.

- Premium Quality at Competitive Pricing: Industry-leading products optimized for value and performance.

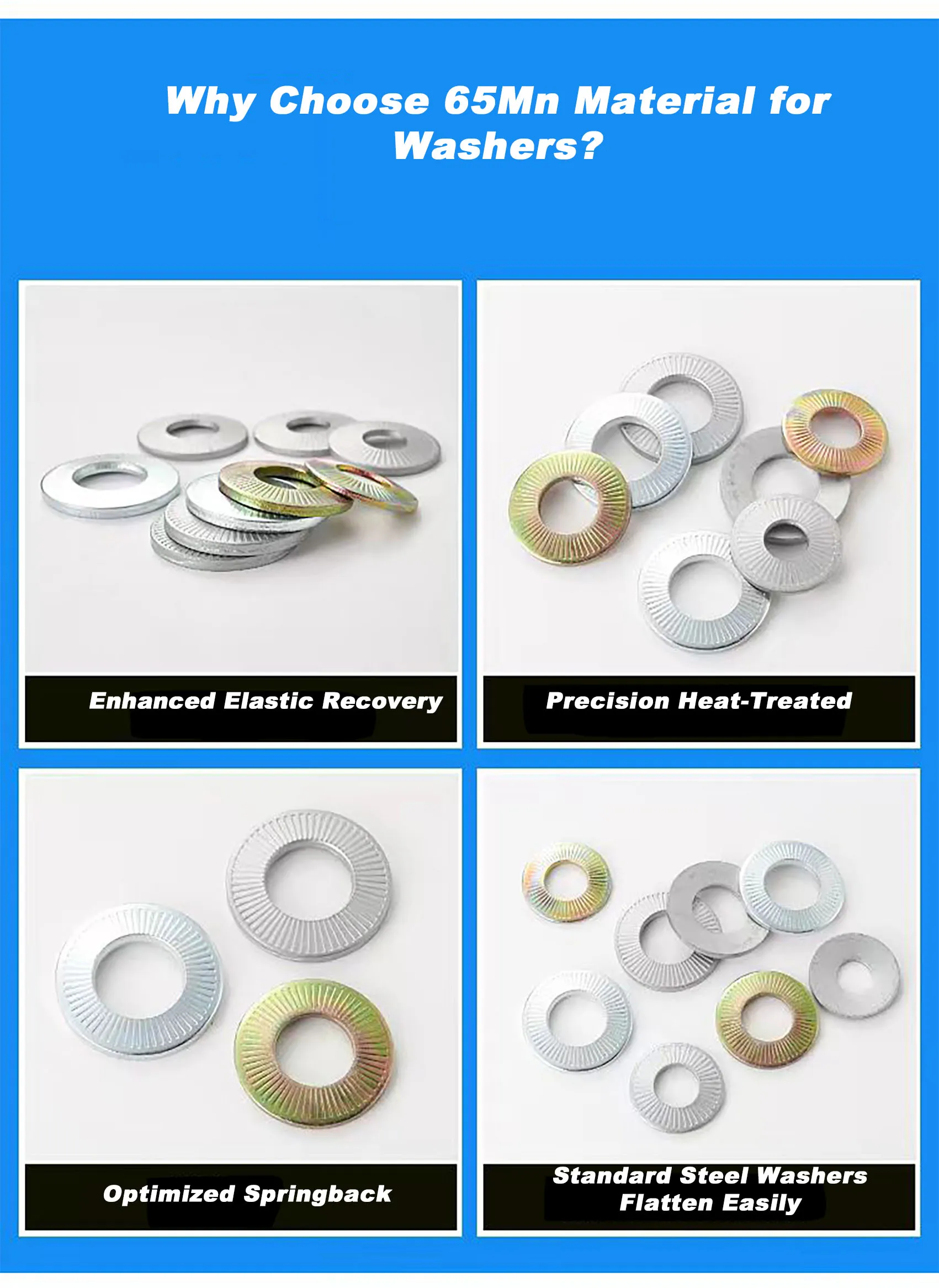

Product Images

Below are the key images demonstrating the Conical Knurled Spring Washer's design and applications:

Read More About a spring washer is a type of

Read More About spring washer types

Read More About spring lock washer types

Read More About disc spring washer manufacturers

Read More About disc spring washer manufacturers

Conclusion

The Conical Knurled Spring Washer from HEBEI A&Z INTERNATIONAL CO., LTD. exemplifies the synergy between advanced materials and innovative design. Its technical specifications, including corrosion resistance, vibration resistance, and temperature tolerance, make it a versatile solution for aerospace, automotive, and industrial applications. With over two decades of global export experience and a commitment to quality, HEBEI A&Z INTERNATIONAL CO., LTD. continues to set industry benchmarks in fastening solutions.

References

National Institute of Standards and Technology (NIST)