Fastening solutions are critical in modern manufacturing, where precision, durability, and reliability are non-negotiable. The Conical Knurled Spring Washer emerges as a revolutionary product designed to address the challenges of vibration, loosening, and environmental stress in fastening systems. This article explores the technical specifications, engineering advantages, and applications of this advanced washer, while highlighting the expertise of its manufacturer, HEBEI A&Z INTERNATIONAL CO., LTD.

Technical Specifications

The Conical Knurled Spring Washer is engineered with precision to meet the demands of industrial applications. Below is a detailed breakdown of its specifications:

| Attribute | Specification | Engineering Advantage |

|---|---|---|

| Material | 304/316 Stainless Steel (AISI Compliant) | Salt spray resistance 500+ hrs (ASTM B117) |

| Design | Conical spring + 360° knurled contact face | 200% higher anti-vibration force vs. standard serrated washers |

| Locking Mechanism | Radial knurls bite into substrate | No pre-drilling. Zero galling on soft metals |

| Fastener Sizes | M3 to M16 (DIN 6796 / ISO 10683) | Full compatibility with ISO metric bolts |

| Temperature Range | -55°C to +300°C (316SS variant available) | Suitable for aerospace/automotive |

| Certifications | RoHS 3, REACH, DIN 6796 Type A | Global compliance guaranteed |

Engineering Advantages

The Conical Knurled Spring Washer is not just another fastening component—it is a result of advanced engineering that addresses common challenges in mechanical systems. Here are its standout advantages:

Superior Anti-Vibration Performance

With a 200% higher anti-vibration force compared to standard serrated washers, this product excels in environments where mechanical stress and vibration are prevalent. The conical spring design combined with the 360° knurled contact face ensures a secure grip, preventing fasteners from loosening over time. This is particularly critical in industries like aerospace and automotive, where even minor failures can have catastrophic consequences.

According to the National Institute of Standards and Technology (NIST), vibration-induced failures are a leading cause of mechanical system degradation. The Conical Knurled Spring Washer's design aligns with NIST's emphasis on robust mechanical solutions to mitigate such risks (NIST).

Enhanced Locking Mechanism

The radial knurls on the washer bite into the substrate, creating a mechanical lock without the need for pre-drilling. This not only simplifies installation but also prevents galling on soft metals—a common issue with traditional washers. The absence of pre-drilling reduces material waste and labor costs, making it a cost-effective solution for manufacturers.

Wide Range of Applications

Available in sizes from M3 to M16, the washer is compatible with ISO metric bolts, ensuring seamless integration into global manufacturing processes. Its temperature range of -55°C to +300°C makes it suitable for extreme environments, from cryogenic applications to high-temperature industrial settings.

Applications in Key Industries

The versatility of the Conical Knurled Spring Washer makes it indispensable in various sectors. Here are some of its primary applications:

Aerospace and Automotive

The aerospace and automotive industries demand components that can withstand extreme conditions. The washer's 316SS variant offers exceptional corrosion resistance, making it ideal for use in aerospace engines and automotive undercarriages. Its ability to maintain integrity under high temperatures and vibrations ensures the safety and reliability of critical systems.

Industrial Manufacturing

In industrial settings, machinery is often subjected to continuous operation and mechanical stress. The Conical Knurled Spring Washer's anti-vibration properties and non-galling design make it a preferred choice for securing bolts in heavy machinery, pumps, and conveyor systems.

Marine and Offshore

Marine environments are notoriously harsh, with saltwater corrosion posing a significant threat to fastening systems. The 304/316 stainless steel construction of this washer provides salt spray resistance of 500+ hours, as per ASTM B117 standards. This makes it suitable for shipbuilding, offshore platforms, and marine equipment.

Company Background: HEBEI A&Z INTERNATIONAL CO., LTD.

As the manufacturer of the Conical Knurled Spring Washer, HEBEI A&Z INTERNATIONAL CO., LTD. has established itself as a leader in fastening solutions. With over 20 years of global export experience, the company specializes in providing certified, high-quality components that meet international standards.

The company's commitment to global compliance is evident in its adherence to RoHS 3, REACH, and DIN 6796 Type A certifications. These certifications ensure that the products meet the stringent requirements of the European Union and other regulatory bodies, making them suitable for international markets.

HEBEI A&Z INTERNATIONAL CO., LTD. also offers customizable spec sheets and instant quote responses, enabling customers to make informed purchasing decisions. Their premium quality at competitive pricing strategy has earned them a reputation for delivering value and performance in the fastening industry.

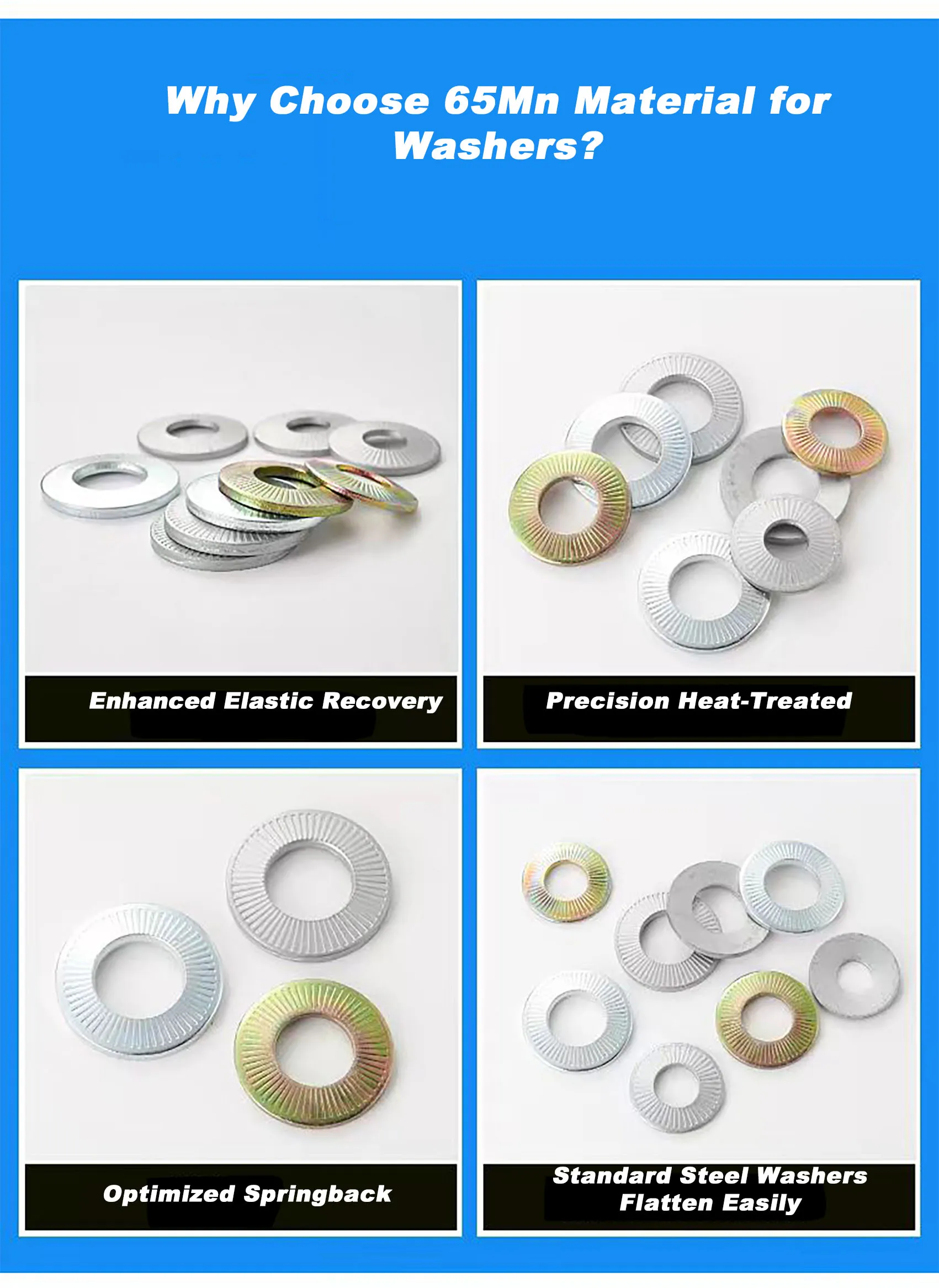

Product Images

Below are images of the Conical Knurled Spring Washer, showcasing its design and functionality:

Why Choose the Conical Knurled Spring Washer?

The Conical Knurled Spring Washer stands out in the market due to its innovative design, superior performance, and comprehensive support from HEBEI A&Z INTERNATIONAL CO., LTD. Here's a summary of its key benefits:

- Advanced Anti-Vibration Technology: Reduces loosening risks in high-stress environments.

- Corrosion Resistance: 500+ hours of salt spray resistance ensures longevity in harsh conditions.

- Compatibility: Full compatibility with ISO metric bolts (M3-M16) simplifies integration.

- Global Compliance: RoHS 3, REACH, and DIN 6796 Type A certifications ensure regulatory adherence.

- Reliable After-Sales Support: Swift technical assistance and 20+ years of export expertise.

Conclusion

The Conical Knurled Spring Washer represents a significant advancement in fastening technology, combining robust engineering with practical applications. Its ability to withstand vibration, corrosion, and extreme temperatures makes it an essential component in industries ranging from aerospace to marine engineering. With the backing of HEBEI A&Z INTERNATIONAL CO., LTD., this product offers not only superior quality but also global reliability and customer-centric support.

For more information about the Conical Knurled Spring Washer, visit the product page. To learn more about the company, explore the HEBEI A&Z INTERNATIONAL CO., LTD. website.

References

1. National Institute of Standards and Technology (NIST). "Vibration-Induced Failures in Mechanical Systems." Retrieved from https://www.nist.gov.

2. HEBEI A&Z INTERNATIONAL CO., LTD.. "Product Specifications and Certifications." Retrieved from https://www.fastenboen.com.