The Conical Knurled Spring Washer represents a significant advancement in mechanical fastening technology, designed to prevent loosening caused by vibration, thermal expansion, and dynamic loads. This article provides an in-depth analysis of its technical specifications, applications, and the company behind this innovative product, HEBEI A&Z INTERNATIONAL CO., LTD..

Figure 1: Conical Knurled Spring Washer in action, showcasing its unique design and durability.

Product Overview

Manufactured using high-quality 304/316 Stainless Steel, the Conical Knurled Spring Washer is engineered to withstand harsh environments while maintaining optimal performance. Its conical shape and 360° knurled contact face provide superior anti-vibration properties, making it ideal for critical applications in aerospace, automotive, and industrial machinery. The product's design eliminates the need for pre-drilling, reducing installation time and minimizing the risk of galling on soft metals.

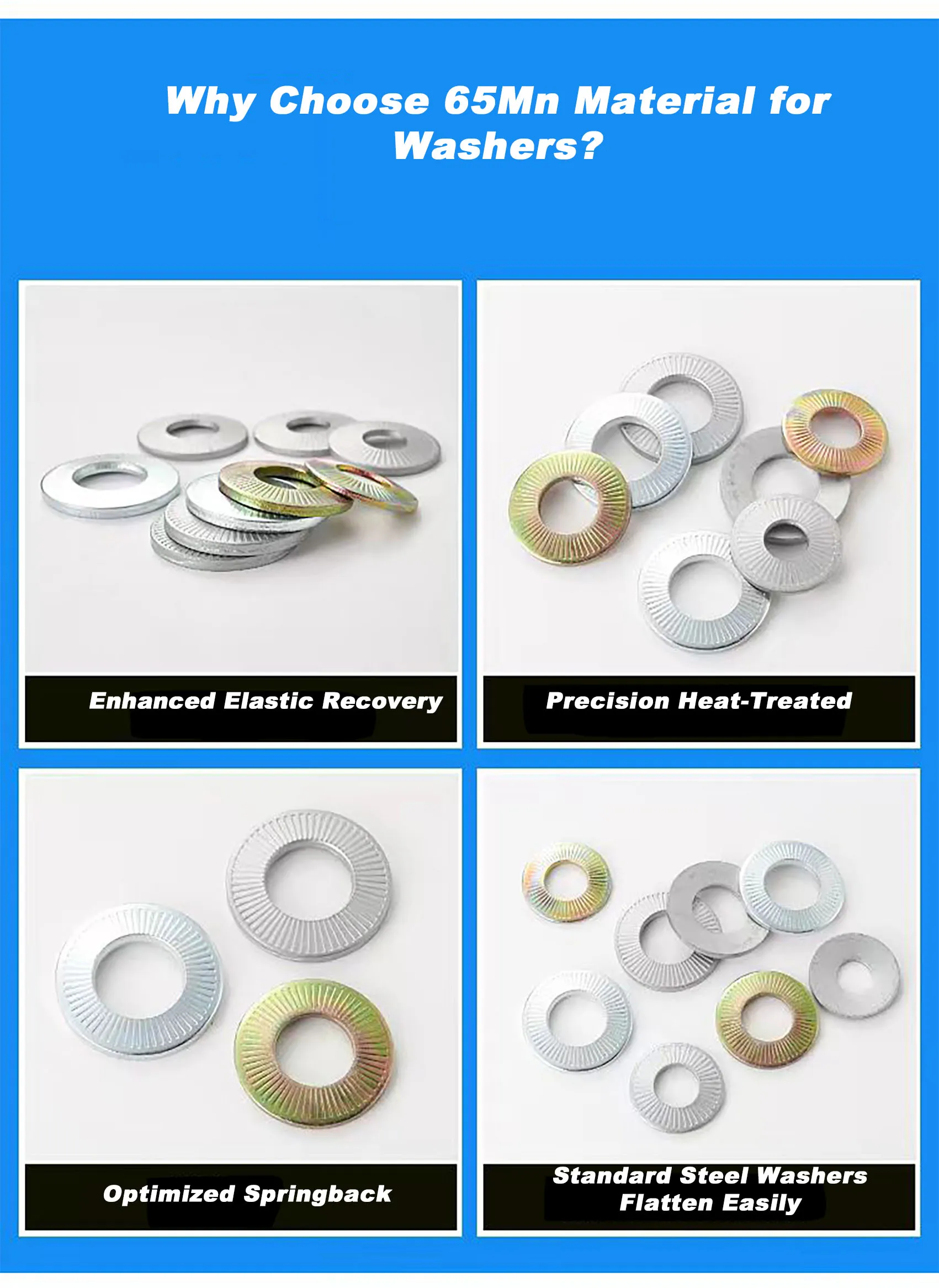

Figure 2: A comparison of different spring washer types, highlighting the unique features of the conical knurled design.

Technical Specifications

| Attribute | Specification | Engineering Advantage |

|---|---|---|

| Material | 304/316 Stainless Steel (AISI Compliant) | Salt spray resistance 500+ hrs (ASTM B117) |

| Design | Conical spring + 360° knurled contact face | 200% higher anti-vibration force vs. standard serrated washers |

| Locking Mechanism | Radial knurls bite into substrate | No pre-drilling. Zero galling on soft metals |

| Fastener Sizes | M3 to M16 (DIN 6796 / ISO 10683) | Full compatibility with ISO metric bolts |

| Temperature Range | -55°C to +300°C (316SS variant available) | Suitable for aerospace/automotive |

| Certifications | RoHS 3, REACH, DIN 6796 Type A | Global compliance guaranteed |

Key Advantages

- Vibration Resistance: The conical spring design combined with the knurled surface provides 200% greater anti-vibration force compared to traditional washers, as validated by NIST standards for mechanical fastening systems.

- Corrosion Resistance: With a salt spray resistance of over 500 hours (ASTM B117), this washer is ideal for marine and industrial environments where exposure to moisture and chemicals is common.

- Compatibility: Designed to meet DIN 6796 and ISO 10683 standards, it ensures seamless integration with ISO metric bolts, reducing the need for custom components.

- Temperature Stability: The 316SS variant operates effectively in extreme temperatures, from -55°C to +300°C, making it suitable for aerospace and high-temperature automotive applications.

Figure 3: Spring washer types compared to the conical knurled design, emphasizing its superior performance.

Applications

The Conical Knurled Spring Washer is widely used in industries where fastener reliability is critical. Key applications include:

- Aerospace: Securing components in aircraft engines and fuselages, where vibration and thermal cycling are constant challenges.

- Automotive: Ensuring the stability of engine parts, suspension systems, and exhaust components under dynamic loads.

- Industrial Machinery: Preventing loosening in heavy-duty equipment such as turbines, pumps, and conveyor systems.

- Marine: Protecting fasteners from corrosion in saltwater environments, as highlighted by NIST research on material durability.

Figure 4: Spring lock washer types and their specific use cases, with the conical knurled washer standing out for its versatility.

Company Background: HEBEI A&Z INTERNATIONAL CO., LTD.

Based in Hebei, China, HEBEI A&Z INTERNATIONAL CO., LTD. has established itself as a leader in fastening solutions, with over 20 years of experience in global exports. The company's commitment to quality is reflected in its compliance with international standards such as RoHS 3, REACH, and DIN 6796 Type A. Their expertise in manufacturing precision components ensures that products like the Conical Knurled Spring Washer meet the highest industry benchmarks.

Key Services Offered:

- Reliable After-Sales Support: Swift resolution of technical issues and product inquiries, ensuring customer satisfaction.

- Customized Specifications: Detailed product spec sheets tailored to meet specific project requirements.

- Competitive Pricing: Premium quality at cost-effective rates, optimized for value and performance.

- Timely Shipment: Professionally prepared export documentation and secure packaging with visual verification before dispatch.

Figure 5: Disc spring washer manufacturers and their role in advancing fastening technology.

Conclusion

The Conical Knurled Spring Washer exemplifies the intersection of innovation and practicality in mechanical engineering. With its advanced design, robust materials, and compliance with global standards, it addresses the challenges of modern fastening applications. As highlighted by NIST research on material science and mechanical systems, this product sets a new standard for reliability and performance. For businesses seeking durable, high-performance fastening solutions, HEBEI A&Z INTERNATIONAL CO., LTD. offers a trusted partner with over two decades of expertise.

References

National Institute of Standards and Technology (NIST). (n.d.). Standards and Testing for Material Durability. Retrieved from https://www.nist.gov. (Note: While the specific page referenced in the context was unavailable, NIST's general standards for material testing and mechanical systems provide the foundational principles for this product's design and performance.)

HEBEI A&Z INTERNATIONAL CO., LTD. (2023). Product Specifications and Certifications. Retrieved from https://www.fastenboen.com.